Brushless motors are a type of electric motor that has gained significant popularity in recent years due to their high efficiency, low maintenance, and reliability. Unlike traditional electric motors that use brushes to transfer electrical energy to the rotor, brushless motors use electronic control systems to power the rotor, resulting in improved performance and reduced wear and tear.

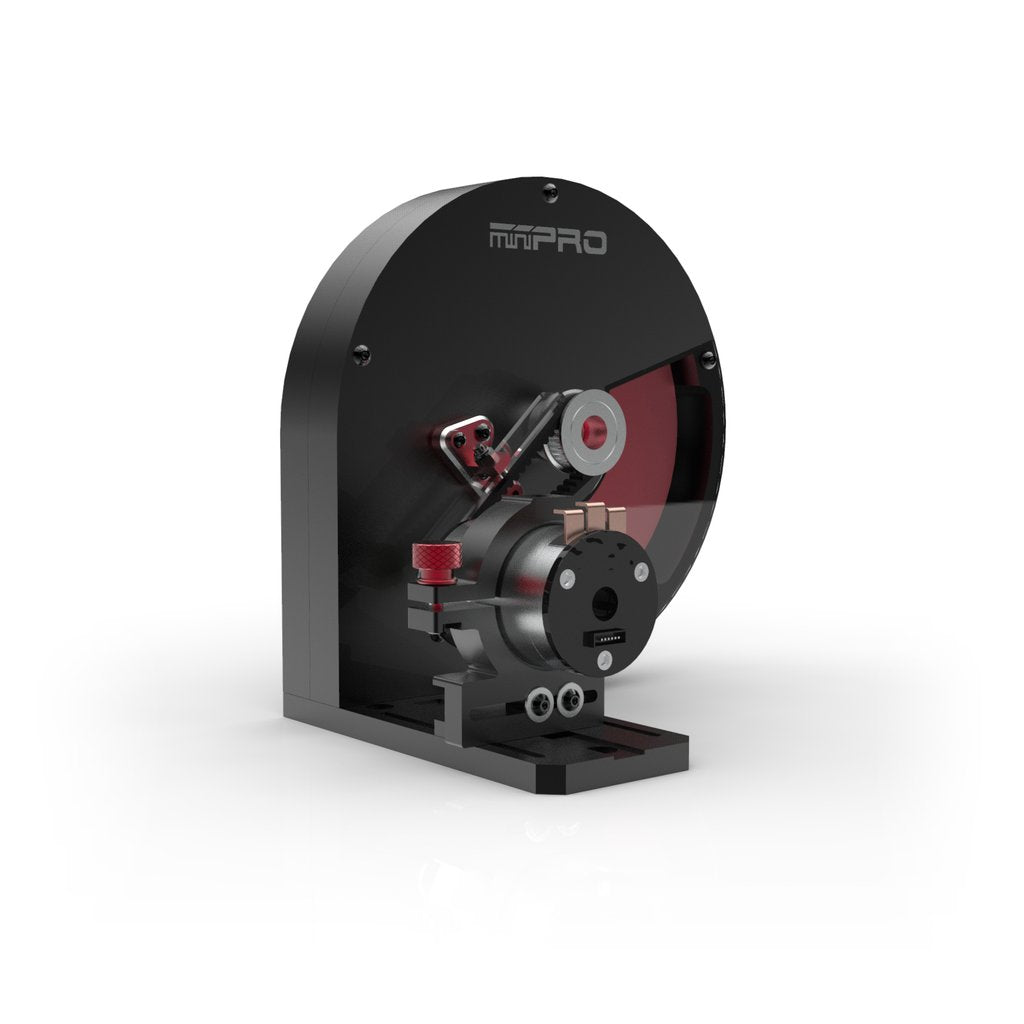

The design of brushless motors consists of a stationary outer ring, known as the stator, and a rotating inner core, known as the rotor. The stator contains a series of copper coils that generate a magnetic field when an electric current flows through them. The rotor is made up of permanent magnets that are attracted to the magnetic field of the stator, causing the rotor to spin.

One of the key advantages of brushless motors is their high efficiency. Traditional motors using brushes to transfer electricity to the rotor lose energy due to friction and wear, resulting in lower efficiency. In contrast, brushless motors use electronic control systems to power the rotor, resulting in less energy loss and higher overall efficiency.

Another advantage of brushless motors is their low maintenance requirements. Because they do not use brushes, there is no need to replace worn or damaged components, reducing the cost and time required for maintenance. Additionally, brushless motors are less susceptible to wear and tear and can operate for longer periods of time without requiring maintenance.

Brushless motors also offer improved reliability compared to traditional electric motors. Because they do not have brushes, there are no moving parts that can wear down or break, reducing the risk of mechanical failure. Additionally, brushless motors are less prone to overheating, making them more reliable in high-temperature environments.

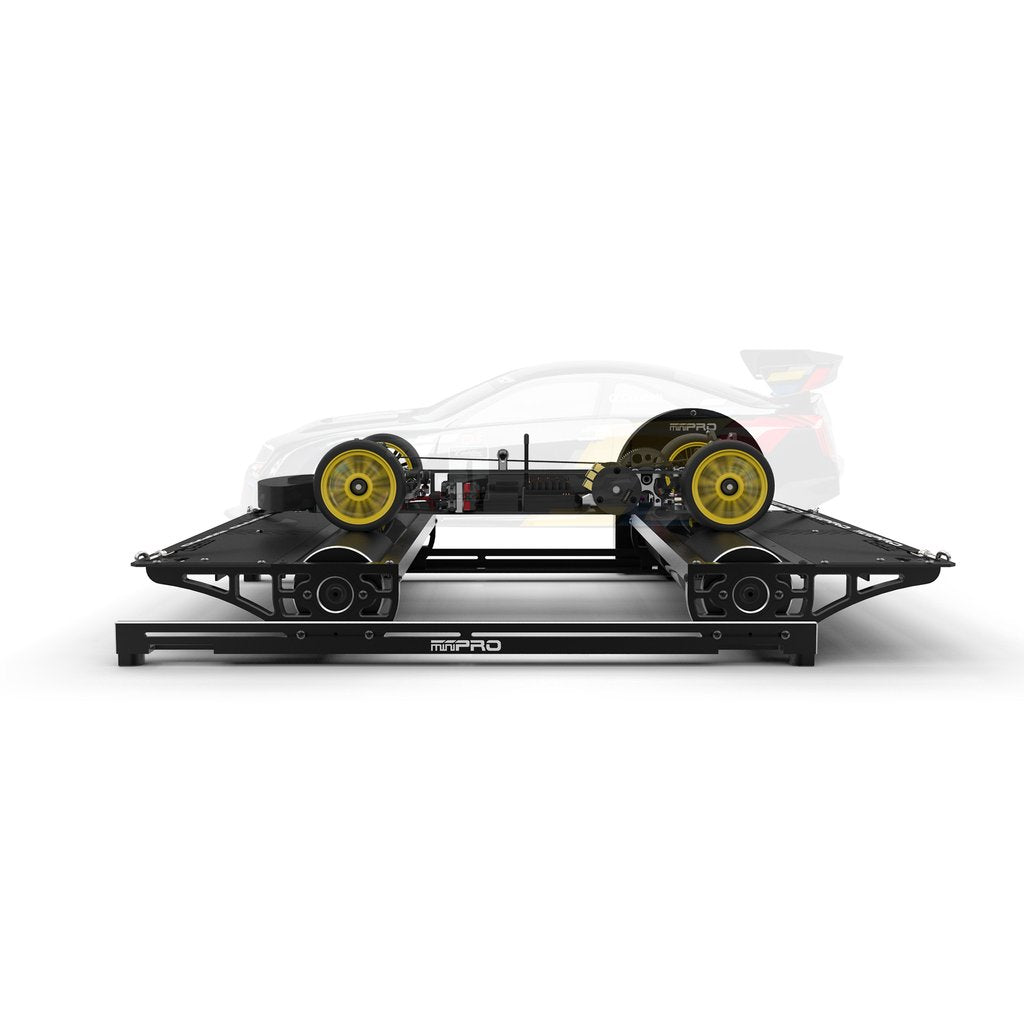

Brushless motors have become increasingly popular in a wide range of applications, including industrial machinery, electric vehicles, and consumer electronics. In industrial settings, brushless motors are used in pumps, fans, and other machinery, where their high efficiency and reliability make them a cost-effective choice. In electric vehicles, brushless motors are used in the propulsion system, where their high torque and efficiency make them ideal for powering the vehicle. In consumer electronics, brushless motors are used in devices such as drones and power tools, where their low weight and high performance are highly valued.

In conclusion, brushless motors offer significant advantages over traditional electric motors, including high efficiency, low maintenance requirements, and improved reliability. As technology continues to advance, brushless motors are likely to become even more widespread, powering a wide range of devices and machinery in a variety of industries.

POST COMMENTS

Leave a comment